- #Inkscape gcode for eleksmaker how to

- #Inkscape gcode for eleksmaker driver

- #Inkscape gcode for eleksmaker trial

Maybe a more powerful laser would make a finer lines? Whether or not this method is better than the toner transfer method to make PCB’s is open to debate. Good for Ortur, Eleksmaker, Neje, Atomstack, LE5040 Sainsmart (Genmitsu).

#Inkscape gcode for eleksmaker how to

It didn’t turn out very well so I didn’t bother trying to etch it. Full guidance of how to convert an image into a gcode using inkscape and jtech. A list of the different G and M-codes can be found here and here. In some cases, it might be the center of the work area.

Most often it will be the rear-right, or front-left of the machine. Usually the home position is in one of the corners. This isnt always the same as where the home position is. Your machine will head toward its origin position. The one on the bottom was a vector cut and was only intended to expose the lines between the traces.This would be an ideal way to etch the board because it preserves more of the copper. In the console window, type G0 X0 Y0 then hit enter. It’s also possible this low powered blue diode laser is just not up to the task. I’m sure with a little more practice I would be able to refine the technique and make a better board. I managed to make a semi-usable SevenSwitch PCB. There was still a thin layer left after lasering but I was able to remove it with some 50% Isopropyl alcohol.

#Inkscape gcode for eleksmaker driver

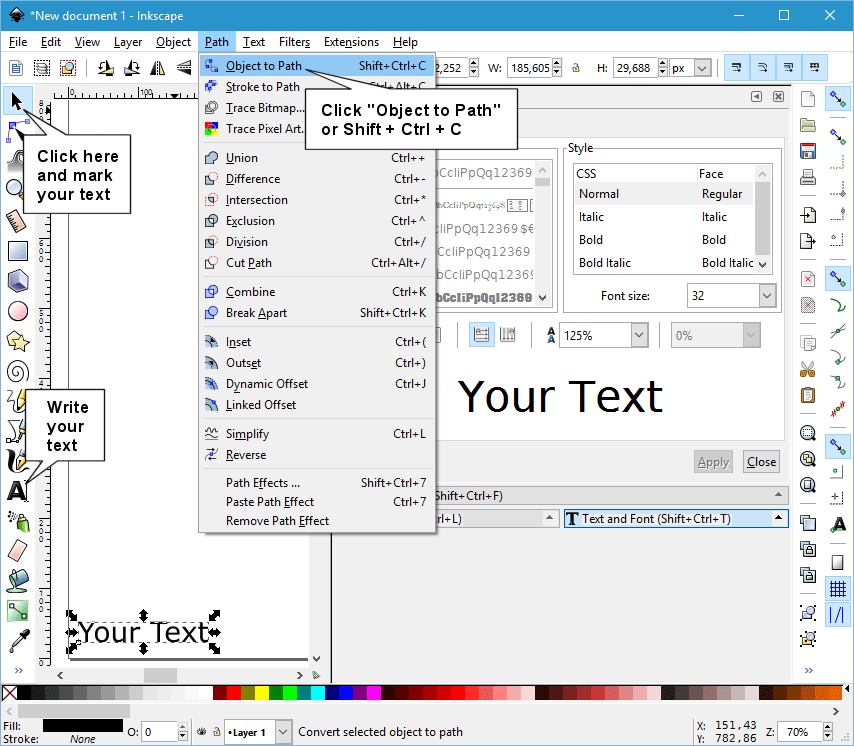

Of everything I tried it was the fingernail polish that produced the best results. So, I made a mashup of scribbles.p圓 and the Egg-Bot Driver for Inkscape4 to bring you the inkscape-unicorn extension for Inkscape Once installed, this extension allows you to save files in 'MakerBot Unicorn G-Code (. After around 30 tries, I gave black fingernail polish a try. I also tried making multiple passes over the board and varying the speed rates but that too had no affect. If you have more than one path, the laser will move down Path Depth (mm) between passes. Click Extensions Generate G-Code for Repetier Repetier Laser Tool to start our plugin. The Plugin will use this path to generate the G-Code. It left a thin layer over the lasered portions that I couldn’t remove without damaging the traces. G-code (also RS-274) is the most widely used computer numerical control (CNC) programming language. Click Path Object to Path or press Shift + Ctrl + C to convert the text into a path. I tried coating the PCB with Matt Enamel Spray Paint, Acrylic paint, a Sharpie marker, Etch resistant pen and all had the same results. It left just enough paint behind to prevent the etching fluid from reaching the copper.

This laser was not powerful enough to remove all of the paint from the surface. From the DIY guides on-line they have you believing that spraying some matte paint on a copper clad board and after lasering the pattern you will be able to just wipe off the scorched area and reveal a nice shiny copper surface for etching.

#Inkscape gcode for eleksmaker trial

It took a lot of trial and error to come up with a somewhat usable board. I didn’t have much success trying to make a PCB with this laser.

0 kommentar(er)

0 kommentar(er)